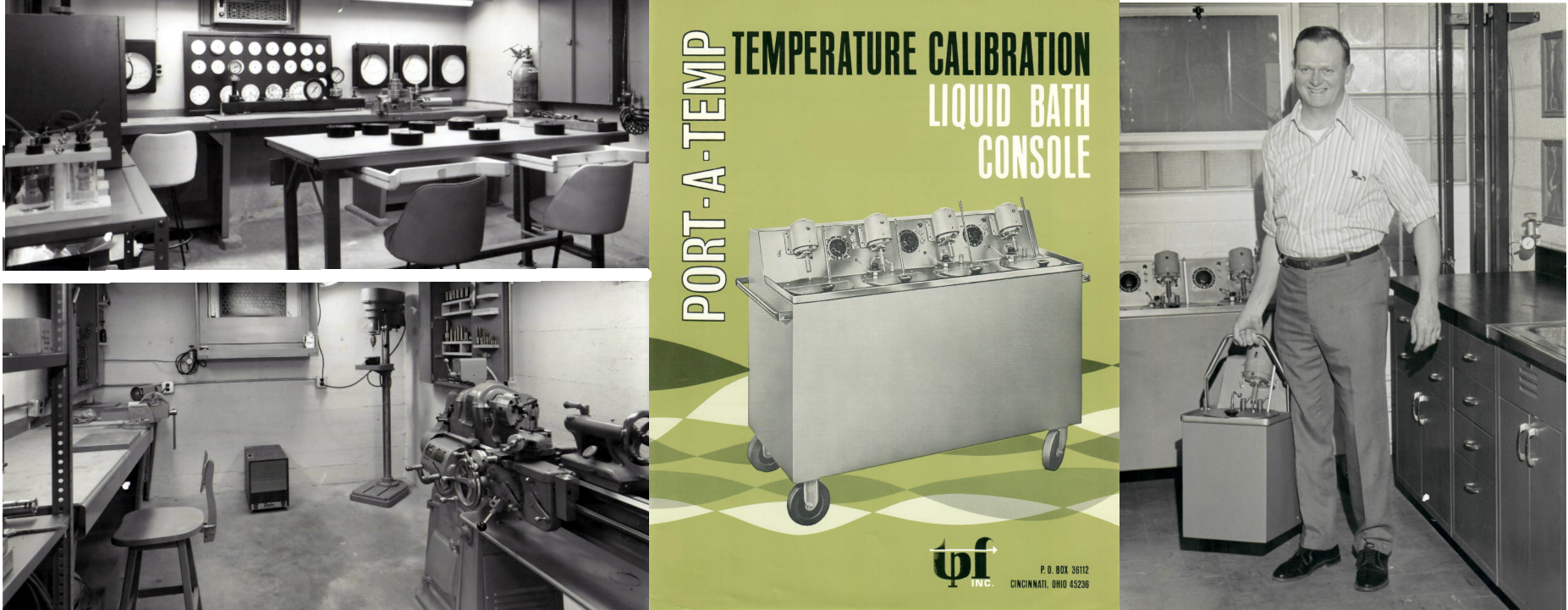

In 1969, Robert Stiens, with the help of two partners, Douglas Hitt and Herbert Kief, formed TPF Inc. - Temperature, Pressure & Flow Products - to offer the finest quality temperature and pressure instruments for industry. Starting in his home, Robert established a repair center for instruments, pressure gauges, diaphragm seals, thermometers, recorders, and safety valves. Some of their first customers are still with TPF: P&G, BP Oil, Dow, John Morrell, Sara Lee Foods, Seagram’s Distillery...

The following year, 1970, as TPF added employees, the need for a larger space became apparent. The facilities at 313 South Wayne Avenue, Lockland, Ohio, fit all its needs and gave it room for expansion.

The company’s first product was the Port-a-Temp, a temperature bath for the thermometer calibration. The unit was well received and many units were sold to rubber companies, chemical companies, and even to Ross Labs, the manufacturer of Similac. It was used in locations all over the world, including Russia.

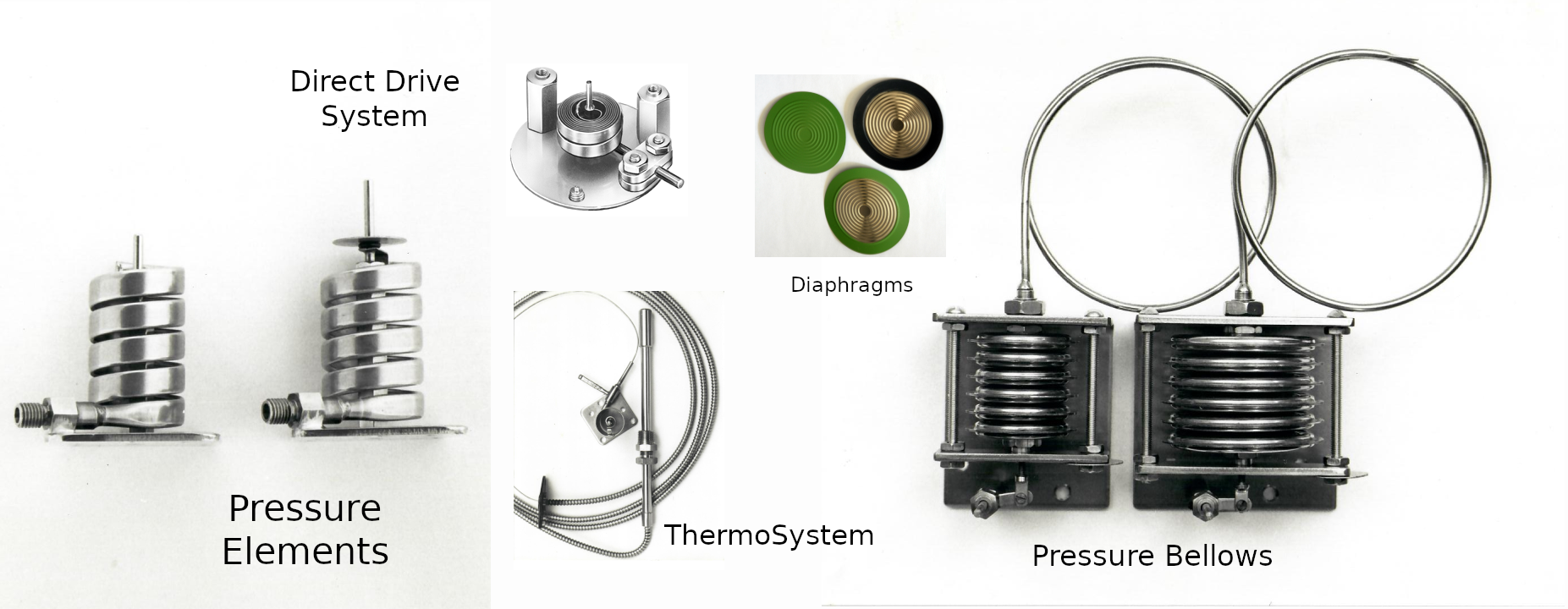

The next product was TPF’s first Bourdon pressure element, all 316SS. It is used on recorders in the natural gas industry: Barton, Mercury, Bristol, Arco, and Reynolds. It was followed by the development of the temperature system, adopted by Reynolds as their standard, and installed by many other manufacturers.

Along the way, TPF was encouraged by customers to certify some of the instruments they used in their testing. TPF began to offer certification services, using the standards required for repair and development: MIL Standard 45662A.

While still growing, manufacturing, repairing, and meeting the customers' needs, TPF continued development and improvement of the Direct Drive System. At last, the first direct drive thermometer units were launched. Standard Oil, a long time repair customer, had a requirement on the pipeline: replace mercury glass tube thermometers. Over the next several years, TPF Dial Thermometers were extensively tested for accuracy and durability, and have proven themselves time and time again. Many of the first units are still in service, 40 years later. The continuing expansion of the thermometer styles has been customer-driven. TPF developed bulbs to fit the thermo-wells already welded in pipelines; remote thermometers on oil tanks to make measurements easier to take; temperatures up to 1200°F (650°C) and temperatures down to -350°F (-200°C); special bulbs; 100ft capillary lengths; -- whatever the customers required.

In the early 1980s the food industry came to TPF with a need to test box beef combos, so Research & Development created some prototypes and now the TPF Combo HD is a standard testing device in the receiving departments of many food processing companies. The food industry returned with another requirement, GET RID OF MERCURY THERMOMETERS, so the TPF Temperature Room Monitor was born - the TRM: no mercury, accurate, easy to read, all stainless steel. This unit has been adopted by all of the major meat processors in the United States.

In the late 1980s the production of the Port-A-Temp was discontinued. The units were too well built! Once a lab had one it never wore out. The latest order for parts was in 2011, over 22 years after the last unit was made.

As customer requirements for testing instruments increased and TPF’s manufactured products were being sent around the world, the need for an international standard became apparent. TPF became ISO 9001 and ISO 17025 accredited. TPF now maintains ISO 17025 for Certification of Pressure and Temperature, following the guide of ISO 9001.

Our latest product, the Overfill Protection Probe, has been a combined development with Marathon Petroleum Co. It is a safety device, used on storage tanks and tanker trucks to prevent overfilling. The 2TPFB probe continues to offer superior detection speed and longevity when compared to other products available today.